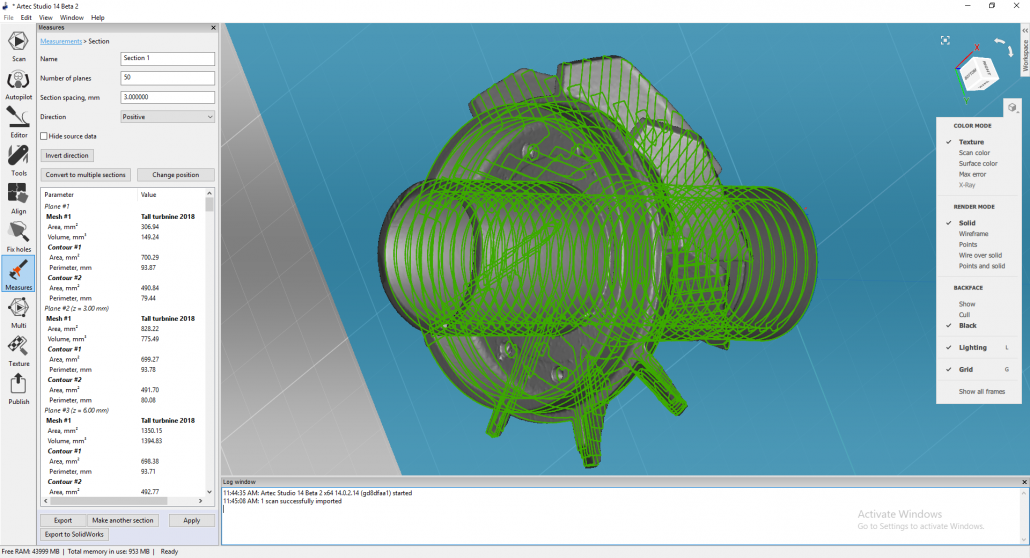

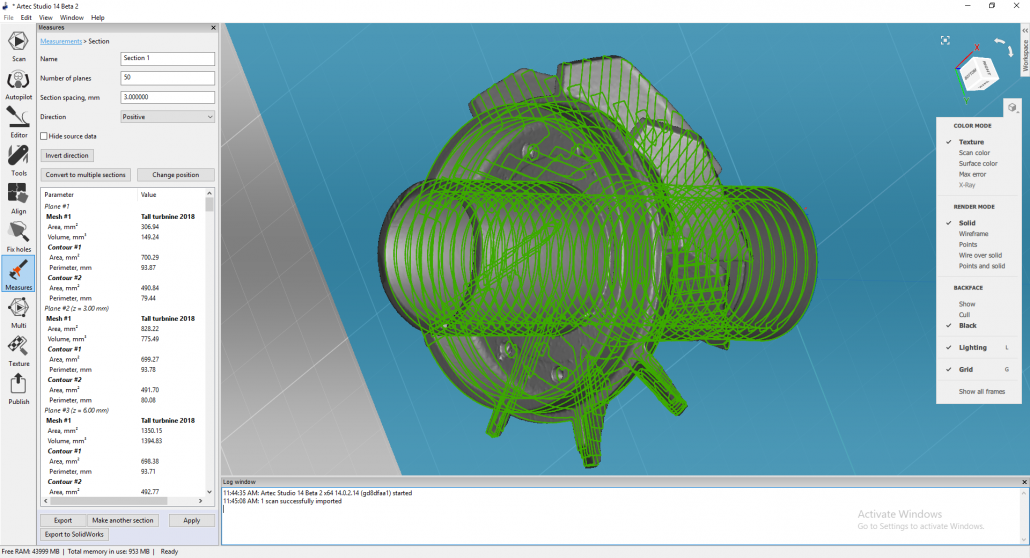

CAD models to validate tooling, even when no current models exist.This application can allow you to conserve valuable resources and manpower. True CAD models for FEA testing of actual geometry to correct problems before parts go into production.Discovering any defects or deviations from the design-intent model will allow you to readjust sooner and keep your project or production on track.

Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model. Fast, ultra-accurate results, reducing your time to market and cutting labor and material needs-saving you both time and money! When compared to traditional hand measuring methods, 3D scanning services are exponentially more efficient, quick, accurate, and detailed. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection, or analysis at any point of a typical manufacturing cycle.ģD laser scanning technology can provide you with: Give our 3D Scan team a call! 95 Raw 3D scan data consists of millions of XYZ data points, called “point clouds,” which can be manipulated and delivered in a number of native file formats. Architecture, Engineering, ConstructionģD Laser Scanning – Over 30 Years and 25,000 Successful Projects Completed!ģD laser scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your object’s shape and geometries. When you’re able to show your designs in 3D verses a static 2D drawing the experience is more realistic.

Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model. Fast, ultra-accurate results, reducing your time to market and cutting labor and material needs-saving you both time and money! When compared to traditional hand measuring methods, 3D scanning services are exponentially more efficient, quick, accurate, and detailed. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection, or analysis at any point of a typical manufacturing cycle.ģD laser scanning technology can provide you with: Give our 3D Scan team a call! 95 Raw 3D scan data consists of millions of XYZ data points, called “point clouds,” which can be manipulated and delivered in a number of native file formats. Architecture, Engineering, ConstructionģD Laser Scanning – Over 30 Years and 25,000 Successful Projects Completed!ģD laser scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your object’s shape and geometries. When you’re able to show your designs in 3D verses a static 2D drawing the experience is more realistic.

Moving from 2D to 3D improves how your ideas and concepts are shown and communicated.

0 kommentar(er)

0 kommentar(er)